20 Middleburgh Street, Troy, NY 12180 • 518-272-0773

Injection Mold Design & Fabrication

Troy Tool & Design excels with plastic injection mold design and fabrication. Whether you’re in need of a rapid aluminum prototype tool or a precision hardened multi-cavity production mold TTE offers rapid quality design and flawless fabrication. Mold welding & repair or refurbishing a substandard tool are also services offered at TTE.

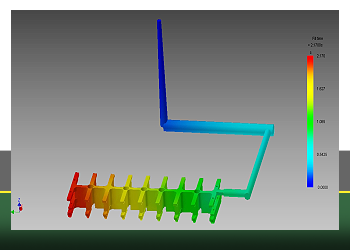

Multi-cavity Injection mold design requires experience coupled with technology to facilitate a synchronized balanced runner design. Part symmetry simplifies the design, but when the part is asymmetric or the tool is a family mold the runner layout requires knowledge of fluid flow for proper operation. For this reason TTE relies on computer simulation to investigate and optimize mold design.

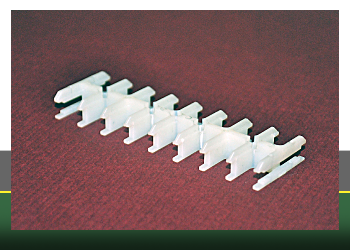

The ABS part to the right was difficult to fill, due to successive thin wall sections that make-up the part geometry. Customer requirements (No weld lines) determined that the part could only be filled from one side. A Moldflow part analysis revealed that maximum fill-pressure and a longer fill-time would be required for this particular geometry. In addition, since the tool was a two-cavity family mold, a standard issue turngate (single part selection) was considered essential. The part was a little difficult to mold, but our team was able to do so without modification of the original geometry. At Troy Tool & Design, our experience coupled with computer-driven simulation tools optimize our design & build repertoire to satisfy our customers’ requirements.

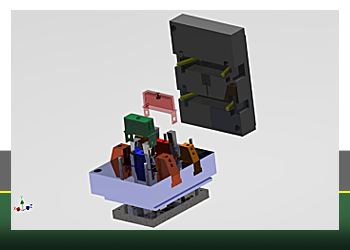

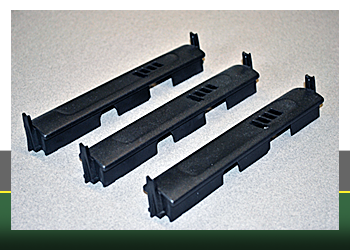

Family tools are not always easy to design or fabricate. However, a clever design can save time and money with both mold fabrication and molding machine time.

But no matter how logical the design it is the Toolmakers skill that makes it work. Upon close examination of the above family mold there are four slides shutting off on four lifters. Our Toolmakers did a fine job, as evidenced by the parts on the right. As usual, first shot produced successful first article and the mold went right into production.